Special-purpose machine for insulator is a SUKEGAWA-WORKS brand, which we have supplied to insulator makers all over the country.

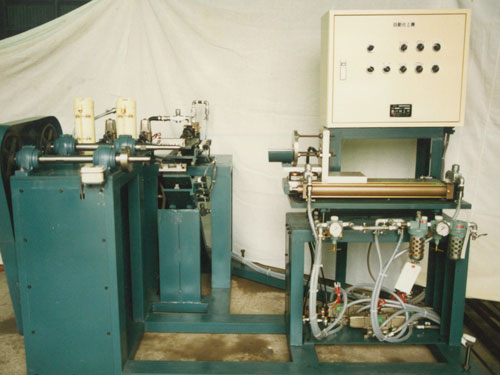

NC lathe

NC lathe

The outer shape of the insulator is cut down using J- bit.

L-shape dual platform setup allows a single worker to control two platforms alternately.

NC lathe/control panel component

Mitsubishi MELDAS is used as CPU. Tool path function is equipped as well.

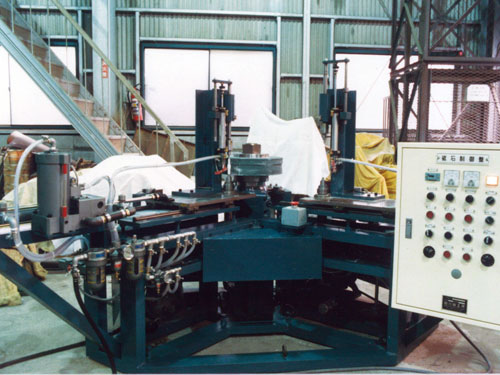

Round trowel molding machine

Top-rotation type hydraulic dual-link round trowel molding machine

The dual link allows compact size, which makes it possible for a single worker to take out “hoke” alternately without large movements.

Top-rotation type hydraulic round trowel automatic molding machine (Split kettle type)

Large-size “hoke” is scooped with lift and put in the split kettle.

Top-rotation type hydraulic round trowel automatic molding machine (push up type)

Molded “hoke” is taken out by pushing it up from the bottom with hydraulic cylinder.

Top-rotation type hydraulic round trowel automatic molding machine (push up type)

Hydraulic servo mechanism allows smooth inching and solves the intake phenomenon during round trowel mold release.

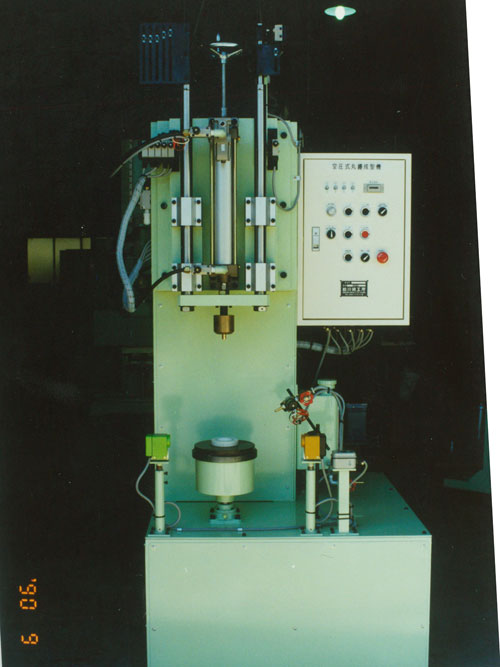

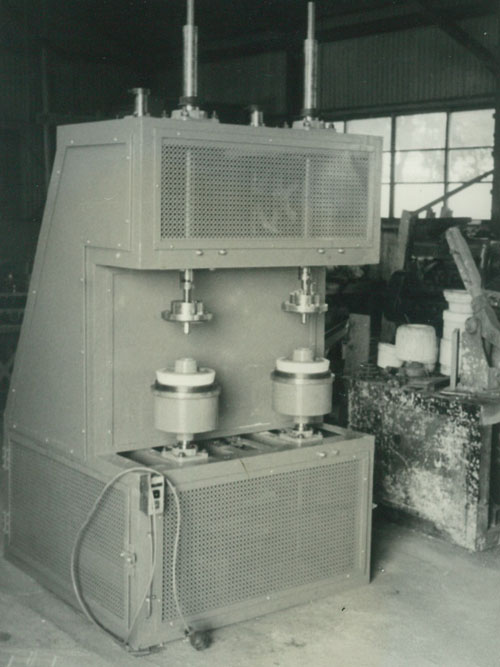

Pneumatic round trowel automatic molding machine (third generation)

Insulator molded with plaster mold is often relatively small in size and thus the pneumatic type, which is more compact and cheaper than hydraulic type, is recommended.

Also, in comparison to the hydraulic type, speed is faster and is more fit for mass production.

Pneumatic round trowel automatic molding machine (third generation)

Pneumatic round trowel automatic molding machine has been improved numerous times to reach a third generation spec.

The body is extremely rigid due to a 16mm steel plate welded structure plus annealing.

空Pneumatic round trowel automatic molding machine (second generation)

The second generation pneumatic round trowel automatic molding machine adopted quenching slide shaft and slide bush, which improved durability and smooth motion.

Pneumatic round trowel automatic molding machine (first generation)

The original pneumatic round trowel automatic molding machine was a revolutionary apparatus whereby the formation process which used to be done by hand was automated using an air cylinder.

Other

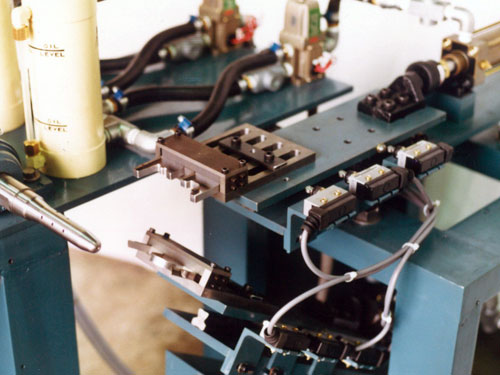

Anchoring automatic finish machine

By using the air cylinder to pierce the “hoke” placed on the catcher on the right with arbor, Thomson blades come out of two locations in order to mold the shape of the insulator by machining.

Anchoring automatic finish machine(Turrets)

By replacing the Thomson blades in the two locations, the cutting shape of the insulator can be changed.

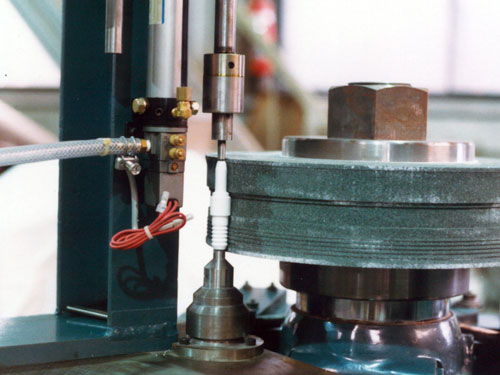

Glow plug outer shape grinding machine

Raw material formed by rubber press is ground into the shape of a plug using a grindstone.

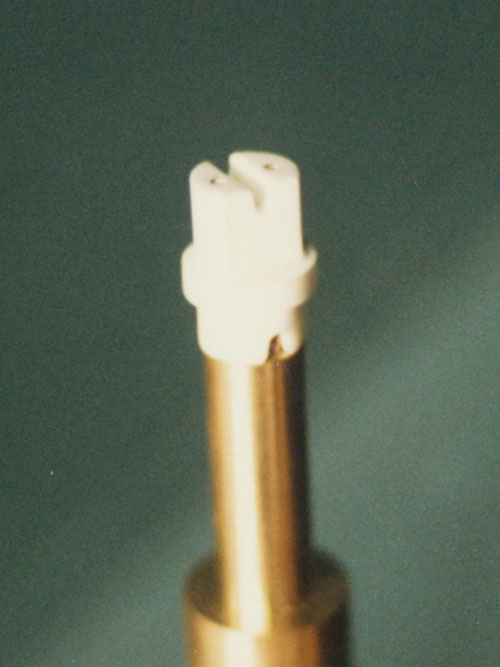

Glow plug grinding stone

Grinding stone, by pressurizing using a same shape male mold and slowly rotating it, can perform shape formation and dressing.

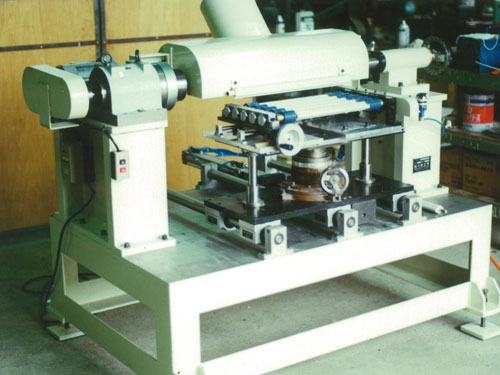

Bobbin automatic grooving machine

5 pieces of ceramics are set and layered grindstone is used to grind a groove on the surface.

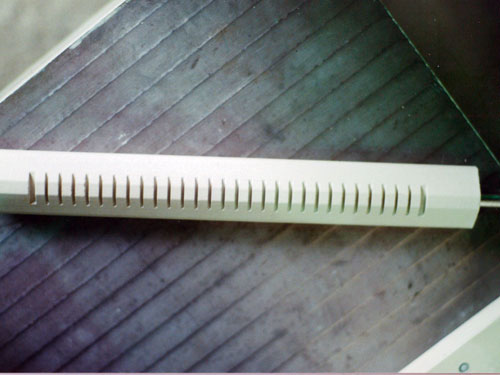

Bobbin groove processing status

30 grooves are ground at once using layered grindstones.

Granulator

Clay block, formed using filter press, and water are inputted, and raw material for wet press is crushed/granulated.

Granulator agitator component

Eccentric agitator (counter-clockwise) and outer shape tank (clockwise) are used for crushing/granulating.

Red line automatic blower

Red line is drawn, using a spray gun, on the outside of the insulator.

Insulator edge polisher

A pneumatic chuck and cutter shifting cylinder is attached to an old machining lathe to polish the insulator edge.

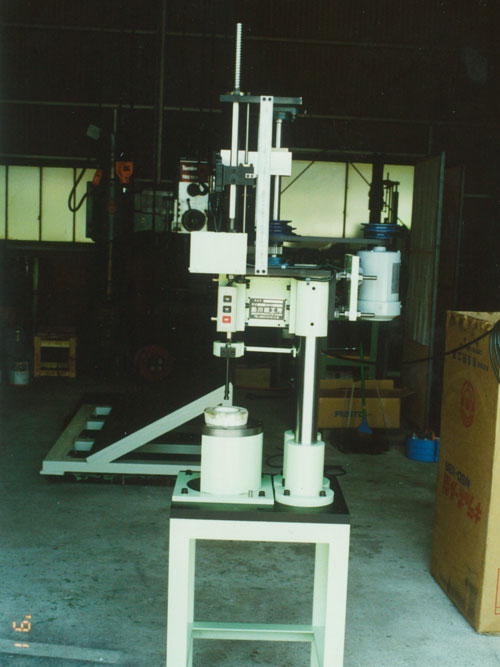

Automatic thread cutting machine (second generation)

Female screw is formed on the inner diameter of insulator.

For the second generation, all components were internally manufactured, thereby improving rigidity and convenience.

Automatic thread cutting machine (first generation)

The original automatic thread cutting machine was a modified version of a machining bore drill press, and it contributed to the shortening of delivery time and low price.

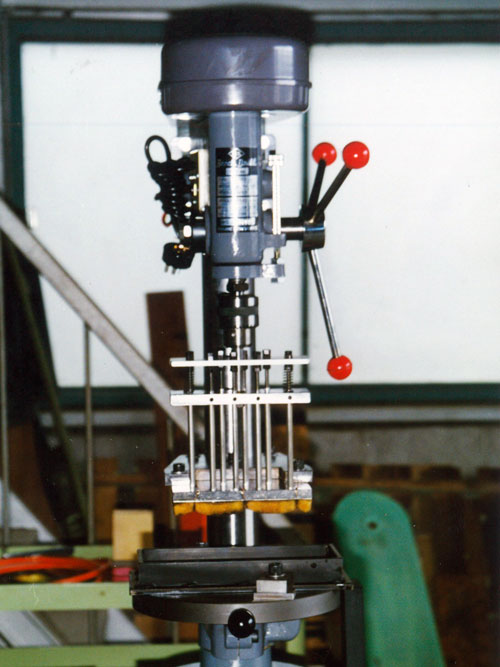

Tap platform round hole puncher

By setting the round hole jib and work catching jig on the machining drill press of the customer, a hole can be punched into the tap platform with ease.

Automatic clay block cutter

Since cutting is done by synchronizing to the speed at which the clay comes out of the kneading machine, the cut is done at a right angle.

Blow glazing machine

Glaze is applied using a spray gun.

Glazing work

Insulator the size of a thumb is coated on top of dual-linked jig.

Insulator torsion damage test machine

Torsion pressure is applied to a large insulator to test how much force it can withstand.

Round trowel

Various round trowel

Metal mold indispensable for shaping the inside of an insulator using a molding machine.

All of the escape grooves for the excessive clay to exit during the molding used to be carved out by hand.

*Production ended as of October 2006.

We would like to thank you for your many years of continued support.

Various round trowel

Metal mold for insulator with deep corrugation such as suspension, salt resistance and pin insulator.

Prized pictures

Anchoring automatic finish machine (cam drive)

During an age in which air cylinders were yet to be popularized, cam drives were the motion of the cutter for the outer shape finish.

Picture from late 60’s to early 70’s.

Outer shape grinder

During an age in which air cylinders were yet to be popularized, the mechanism for holding the work was a cam-type. You can feel the history from the shape of the motor.

Picture from late 60’s to early 70’s.

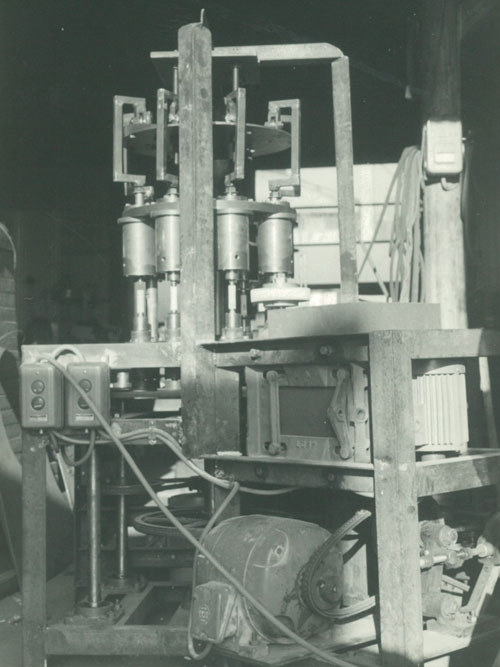

Round trowel automatic molding machine (cam drive)

During an age in which air cylinders were yet to be popularized, the mechanism for moving the round trowel up and down was a cam-type.

Picture from late 60’s to early 70’s.

High frequency test machine

Insulator post-firing is artificially sparked to inspect whether there is iron mixed in.

The “Suzuki Carry FB” in the back gives you the feel for the history.

The picture was taken in 1964.