Comparison of solid lubricant wax and lubricant

Introduction

Solid lubricant by itself does not provide low friction or cooling effect such as from oil or grease, yet its lubrication effect is demonstrated in areas where use of oil and grease is difficult or unfavorable.

Particularly, the effect is expected in friction/wear reduction in extremely harsh environment such as lubrication of sliding surface that moves super heavy objects or plastic processing requiring load carrying capacity above the yield stress of metal material.

Generally, the slower the speed, such as when speed is zero at start or stop, the more difficult it is for oil film of oil or grease to form, that is, fluid lubrication, which causes wear to occur easily through adhesion of friction surface. The reciprocating component of a crane wheel, which repeats starting and stopping movement is especially problematic.

A solid lubricant can maintain lubricity regardless of start and stop, which make it effective for preventing friction and wear in such cases.

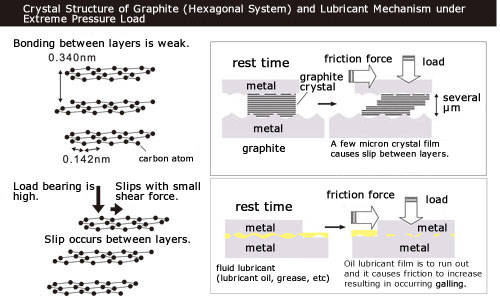

In case of lubricant, the friction surface under an extreme-pressure load such as in a crane wheel causes discharging of oil film of base oil lubrication without additives, causing fretting wear between metals.

However, solid lubricant such as molybdenum disulfide having a hexagonal structure, as long as several μm particles are present on the friction surface, because it has high load resistance, causes sliding from a small shearing force, and as a result, discharging of particles from application of external pressure does not occur.

The above was tested through lubricant performance tester.

Scientific Study:Four Ball Load Carrying Capacity Test (Shell type)

Standard Test Method:ASTM D 2596

Specification

Test Ball : Steel Balls for Ball-Bearing

Ball Spherical Diameter : 12.7mm

Rotation Speed (Upper Pivot Clamp) : 1760±60rpm (Configurable)

Test Sample Temperature : 27±8℃ (Configurable)

Application Quantity :Arbitrarily applied (Sufficient is applied to fill air gap of test cup and surface of steel balls)

Time : 10 seconds (Configurable)

Load : 78 ˜ 7845N

Research information : Last Non-seizure Load (LNL), Weld Load (WL), Load Wear Index (LWI)

Purpose

The Four Ball Load Carrying Capacity Test (Shell type) is a testing used to determine the Load Carrying Capacity of the test sample ( oil, grease, solid lubricant etc…).

Refer to Photo 1, 2

Test Method

While keeping this condition, the upper pivot clamp is rotated at a speed of 1760±60rpm for 10 seconds. Repeat operation until welding of the steel balls occurs by increasing loads and changing the steel balls.

The wear scar diameters on the test ball and test load are used to calculate the Load Wear Index (LWI), Weld Load (WL) and Last Non-Seizure Load (LNL). LNL is the load just before the seizure occurs. WL is the load when steel balls weld into one. LWI is the comprehensive index of lubricant load carrying capacity calculated at the test result. The higher the each figure is thought of as the higher performance.

| Test Load Details(unit:N) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 78 | 98 | 128 | 157 | 196 | 235 | 314 | 392 | 490 | 618 | 785 |

| 981 | 1236 | 1569 | 1961 | 2452 | 3089 | 3923 | 4903 | 6080 | 7845 | |

| The Result of Four Ball Load Carrying Capacity Test (Shell type)(unit:N) | |||||

| Test condition | Bordon Wax | Mineral Gear Oil 100 | Mineral Gear Oil 460 | Mineral Oil(VG100) | |

| Bordon Wax:100℃ Lubricating Oil:20℃±15℃ 1765rpm,10sec |

LNL | 618 | 618 | 618 | 314 |

| WL | 4903 | 1569 | 1961 | 1236 | |

| LWI | 594 | 273 | 295 | 151 | |

【Test Results】

[Comparison of Load Carrying Capacity Between Bordon Wax and Lubricating Oil]

LLast Non-Seizure Load Rate (LNL)

LNL indicates the limit load when seizure starts by metal to metal contact after oil film (lubricating film) is broken by load.

- In comparison with mineral oil Bordon wax indicated higher rate.

- This is because even at such load where oil film by mineral oil is broken Bordon wax film is not. Bordon wax containing high concentration molybdenum disulfide prevents metal to metal contact with its existence between layers.

- Bordon wax has equal LNL rate to gear oil demonstrating such high ability of lubricity as the gear oil mixed with high concentration extreme pressure agent at the heavy load range.

Weld Load Rate (WL)

WL is the load when each metal welds by frictional heat arising from sliding along and it is no longer able to slide along at this range.

- In comparison with mineral oil Bordon wax indicated much higher rate.

- Also, in comparison with gear oil Bordon wax indicates higher rate. This demonstrates the ability of solid lubricant film containing molybdenum disulfide is higher than that of film formed by extreme pressure agent mixed into gear oil when reacting on sliding material.

- The wax is also superior in yield to fluid lubricating oil flowing down.

- The molybdenum disulfide holds first-rate coefficient of friction among solid lubricant withstanding such extreme pressure load as 28ton/㎠. This solid lubricant film significantly increases its limit load.

Load Wear Index Rate (LWI)

LWI is calculated from wear scar diameter between loads resulting from the metal to metal contact demonstrating the higher numeric, the higher wear resistance.

- Bordon wax demonstrated higher numeric than not only mineral oil but gear oil. Therefore, this demonstrates Bordon wax has the superior wear resistance.

Comprehensive evaluation

- Bordon wax has higher numeric rate comparing with mineral oil at all numerical analysis and it is the superior lubricant to mineral oil in load carrying capacity.

- Also its numeric rates show same or higher level comparing with gear oil and it is the superior lubricant to gear oil in load carrying capacity.